JULY at DIVISEGUR

DIVISEGUR at JULY.

There have been many news that we have published in social networks in the month of July. For this reason, we wanted to group them in this post to get an overview of how our activity has gone in this period.

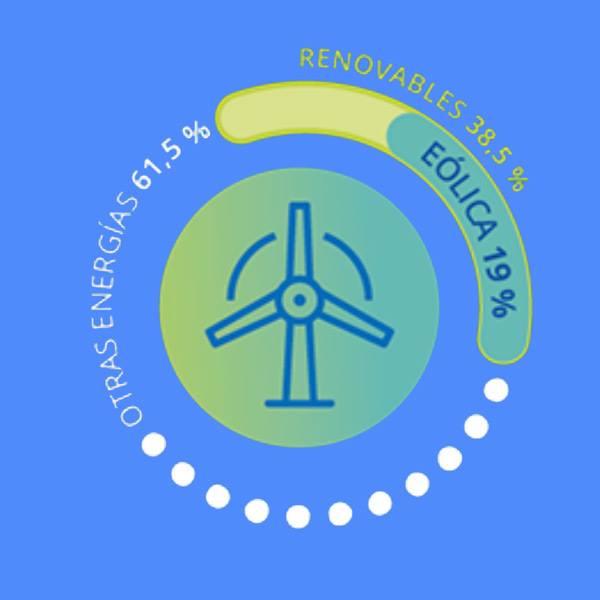

Information about Wind Energy

We have already informed you on several occasions about the importance of wind energy in terms of national production. We have also told you that renewable energy production is above 38% and, specifically, wind energy stands at 19%, which represents the production of half of energy generation and its output is increasing. From DIVISEGUR we want to continue believing in this energy and, therefore, we are one of the leading companies in the sector of maintenance of wind farms, as well as the manufacture of components and parts for their construction.

At DIVISEGUR we continue growing.

Now we show you a new plasma cutting machine, whose function is to offer a better finish, precision and cleanliness in the obtained pieces. The quality and perfection in our work motivates us and, for this to happen, it is necessary, among others, to have the best technology on the market. For this reason, we continue to grow and be a benchmark in the sector.

#wind #service #welding #safety #windpower #fabrication #tooling #iwe #quality #NDT

Ready for extreme conditions

When our parts go to a port or directly to the sea, the surface finish is exposed to the most demanding conditions. How do we guarantee durability for more than 15 years under these conditions? At DIVISEGUR we offer the full range of corrosion protection according to ISO 12944, from indoor finishes (C1) to marine environments (C5-M).

#wind #windpower #fabrication #quality #bespoke #offshore #finish

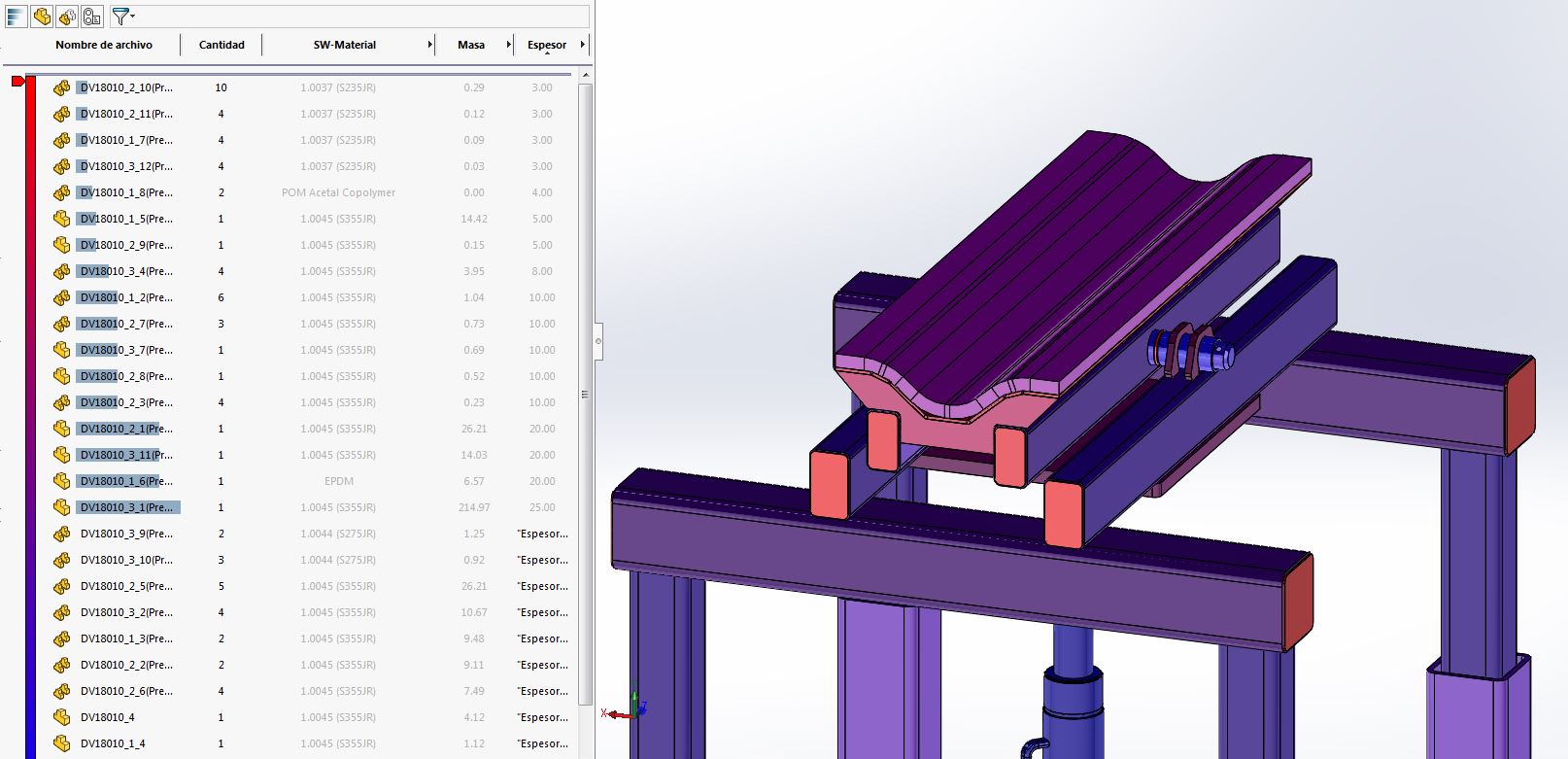

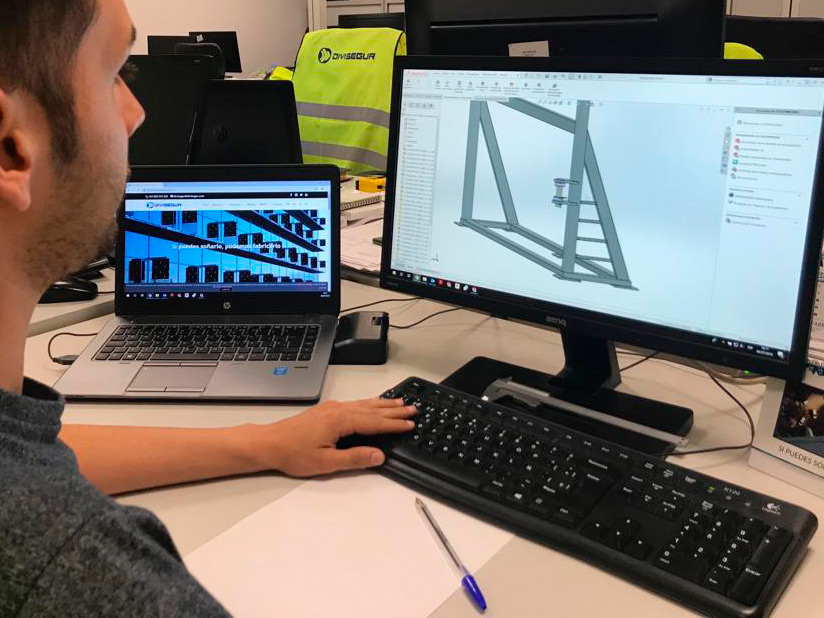

At DIVISEGUR we are passionated about creating.

From the conceptual design of the solution to the implementation of the finished product, we take care of everything.

Our engineers put all their know-how and dedication into each project to ensure that the materials used are the best available and the technical solutions are the most appropriate.

Automation in pursuit of perfection

At DIVISEGUR, following our automation strategy, we have implemented a new machine that automatically polishes and derbars the cut pieces, allowing us to process large quantities of metal plates to improve the quality of our welding and the final finish.

Few things can escape our 25m shot blast tunnel.

At DIVISEGUR we have our own painting facilities with great capacity and, among its different areas, the blast cabin also adapted for railways stands out.

The quality of our products is the result of a series of processes that ends in the priming of textures and coatings depending on the use and conditions that will endure that piece.

Transporting wind turbine components all over the world, requires us to manufacture the most unbelievable solutions.

The swivel joints shown in the picture are part of a complex rail transport system for wind turbine blades in the United States.

At DIVISEGUR we design and manufacture any type of piece that our customers request, either with our own design or provided.

R+D is the way.

At DIVISEGUR we are convinced of this and for this reason our engineering and design department has an excellent technical team equipped with the latest CAD tools that allow us to provide competitive and sustainable solutions to the problems presented by our customers in the field of engineering.

#quality #bespoke #wind #windpower #tooling #engineering #design

Information about Wind Energy

Wind energy is fully competitive and its technology is highly consolidated. The Spanish wind industry has 100% of the value chain located in our country and is prepared to take advantage of job creation, R&D development, generation of social and economic benefits for the environments where the new wind farms are manufactured and installed and, in general, a greater economic backbone for the Spanish territory.

At DIVISEGUR we are convinced that it is the energy of the future and every day we work hard to make it more present.